Properties

Carbon fibres are non isotropic and displays greatest strength lengthwise through the fibres. This means that when producing a sheet of carbon fibre, it is important to have all fibres aligned parallel to each other. Consequently, when using such sheet to produce a car part, the fibres must be aligned with the forces that will act upon that element to make sure it can handle the forces going through the item when in use.

Lengthwise through the fibres, carbon is an extremely strong material compared to its weight. The below table also shows that carbon fibres are both stronger and lighter than steel.

Material Tensile strength (MPa) Density (g/cm³) Tensile modulus (MPa)

Carbon fiber (Toray T700G) 4900 1.80 230

Carbon fiber composite (with Toray T700G) 2550 135

Aramid (Kevlar 29) 3757 1.44 70.5

Steel (ASTM A36) 450 7.90 200

Pure copper 220 8.92 120

The Making Of The Lexus LFA Supercar (Full Article)

www.thetruthaboutcars.com/2012/07/the-making-of-the-lexus-lfa-supercar-who-what-where-and-most-of-all-why-an-inside-report-chapter-1-from-a-bar-to-bar-none/

(In Short Summary)

Carbon fiber reinforced polymer(CFRP) has an unsurpassed strength-to-stiffness-to-weight ratio. CFRP also comes at unsurpassed cost. It entered car making with race cars, where money is no object.

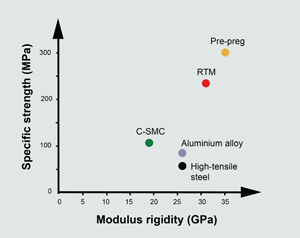

Basically, there are three different ways of making CFRP: Pre-preg, Resin Transfer Molding, (RTM), and Sheet Molding Compound (SMC), listed in the order of strength and expense. The LFA uses all three methods, depending on the required characteristics of the CFRP parts.

Pre-preg is the method to make the strongest type of carbon fiber available. It is also the most expensive when the part is cured in an autoclave.

Carbon fibres are non isotropic and displays greatest strength lengthwise through the fibres. This means that when producing a sheet of carbon fibre, it is important to have all fibres aligned parallel to each other. Consequently, when using such sheet to produce a car part, the fibres must be aligned with the forces that will act upon that element to make sure it can handle the forces going through the item when in use.

Lengthwise through the fibres, carbon is an extremely strong material compared to its weight. The below table also shows that carbon fibres are both stronger and lighter than steel.

Material Tensile strength (MPa) Density (g/cm³) Tensile modulus (MPa)

Carbon fiber (Toray T700G) 4900 1.80 230

Carbon fiber composite (with Toray T700G) 2550 135

Aramid (Kevlar 29) 3757 1.44 70.5

Steel (ASTM A36) 450 7.90 200

Pure copper 220 8.92 120

The Making Of The Lexus LFA Supercar (Full Article)

www.thetruthaboutcars.com/2012/07/the-making-of-the-lexus-lfa-supercar-who-what-where-and-most-of-all-why-an-inside-report-chapter-1-from-a-bar-to-bar-none/

(In Short Summary)

Carbon fiber reinforced polymer(CFRP) has an unsurpassed strength-to-stiffness-to-weight ratio. CFRP also comes at unsurpassed cost. It entered car making with race cars, where money is no object.

Basically, there are three different ways of making CFRP: Pre-preg, Resin Transfer Molding, (RTM), and Sheet Molding Compound (SMC), listed in the order of strength and expense. The LFA uses all three methods, depending on the required characteristics of the CFRP parts.

Pre-preg is the method to make the strongest type of carbon fiber available. It is also the most expensive when the part is cured in an autoclave.